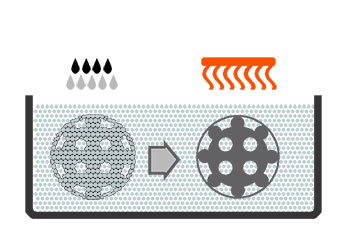

MULTI JET FUSION (=MJF) describes an additive manufacturing procedure which uses two Inkjet printheads to apply special binder-agents to the powder. Both HP Thermal Inkjet Agents use ultra-fine droplets: the black fluid with a high thermal conductivity binds the powder for the actual building process. The colorless liquid is used as a thermal inhibitor at the edges of the part to be build. The bound particle’s fusing is activated with infrared energy leading to a very high surface quality and sharp edges due to the use of the thermal inhibitor component. .

It‘s one of the most productive and at the same time cheapest procedures – mainly used for prototypes and small batches.

Another outstanding advantage compared to conventional manufacturing processes comes with the very short production periods for highly complex, three dimensional geometries – even with undercuts.

All parts are anthracite-grey.

Application area

functional, durable and suitable for series production prototypes, single pieces and small batches

cost-efficient

complex parts with overhangs

flat parts

small serial parts

Materials

Polyamid PA 12-HP - our standard material in grey for the HP Jet Fusion

Machines

HP Jet Fusion 3D 4210

Laser sintering machine by HP

Laser sintering machine by HP

Building space of 380mm x 380mm x 284mm

These machines are perfect for fast and efficient productions of fully functional small batches and parts with complex geometries.