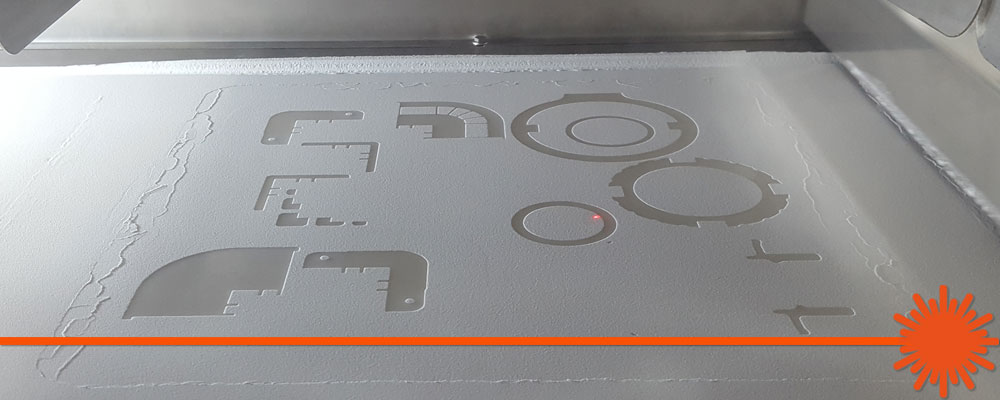

lasersintering | core competence

We are convinced.

We have been working with the former new technology of selective laser sintering (SLS) for well over two decades. Ups and downs, innovations and the return to tried-and-tested methods, we have experienced it all and know the process inside out. The continuous optimization of the building process and the machines itself, we accompanied all the changes and therefore are aware of the chances and the limits a of this technology. We think there is still a lot of potential, for the private market as well as for industrial demands.

We want to convince you as well!

While the first 15 years have been significantly characterized by prototype use, this trend started to reverse and today we are more and more frequently in the fortunate position of delivering small batch series and smaller quantities to the mechanical engineering industry. In such cases our method replaces the traditional injection moulding or CNC machining. This tendency is set to continue and will further develop.

Even the plastic material is subject to the innovation progress. In the meantime we are using a wide variety of materials with manifold characteristics: non-filled as well as filled or additive refined polyamides. Thereby we are able to offer competent solutions for diverse requirements.

For instance contains our portfolio two different surface qualities for the standard material polyamid 2200:

- PA 2200 with the usual high level of detail for good economic efficiency.

- PA 12 smooth with particulary high level of detail and smoother surface for special demands.

Due to our open and personal dialogue with our customers we are able to well understand the market requirements. We are keeping the same close contact with our suppliers and therefore have an always up-to-date portfolio. Promised!

Ask for more – we are happy to assist.